Lightweight Design - It’s an Art: The Audi ASF Design Principle

Most manufacturers' cars have grown heavier as the years have gone by. This isn't true of Audi. Quite the opposite: more than ten years ago the Audi A8 and the Audi A2, with their aluminum bodies, put a stop to this never-ending spiral of increased weight. Since then, Audi has developed this pioneering weight-saving technology more and more. Today ASF (Audi Space Frame), as it is now known, is used for four Audi models: the TT, TT Roadster, R8 and A8.

ASF: the three letters stand for Audi Space Frame – the technology with which Audi has completely reinvented car body construction. ASF is a breakaway from the problem of spiraling weight that has its origins in the growing demands that a modern car must satisfy. The new principle makes a major contribution to the dynamic performance and high efficiency of these Audi models. The TT 2.0 TDI quattro, for example, with its 125 kW (170 hp) diesel engine, sprints up to 100 km/h from a standstill in 7.5 seconds, and has a top speed of 226 km/h. Yet its average consumption is only 5.3 liters of diesel fuel per 100 kilometers, a sensationally low figure.

ASF technology can look back on a development process that has brought Audi a three-figure collection of patents and the "European Inventor of the Year 2008" award from the European Patent Office. The brand now possesses broad-based know-how covering everything from the best metal alloys through casting and forming to suitable component joining techniques.

The framework of an ASF body consists of extruded aluminum sections and pressure castings. This frame carries the sheet aluminum elements, for example the roof panel, which are rigidly connected to it and help to withstand loads on the body. The elements of the Audi Space Frame are very varied in shape and cross-section, depending on the tasks they have to perform. Like the bones of a human skeleton, they combine optimal function with low weight.

The big advantage of extruded sections is their design flexibility. The side sills of the Coupe and Roadster bodies, for instance, look identical, and the same tools and machines can be used to produce them. Inside, however, they are topology-optimized using bionic principles, and the ribs that govern their rigidity therefore have different patterns – the Roadster needs greater rigidity in this area than the Coupe. In all cases, the extruded sections used for the TT's body are made from advanced aluminum alloys, to increase their strength still more and lower their weight at the same time.

The castings, which withstand extremely severe loads, are primarily deployed where high forces are introduced locally and where intelligent multifunctionality is required. A good example is the A-post node, a hi-tech multifunctional component that links the side member, sill, A-post and wind-shield cross-member together. Like all these aluminum castings, it is notable for precision geometry and maximum use of the available space.

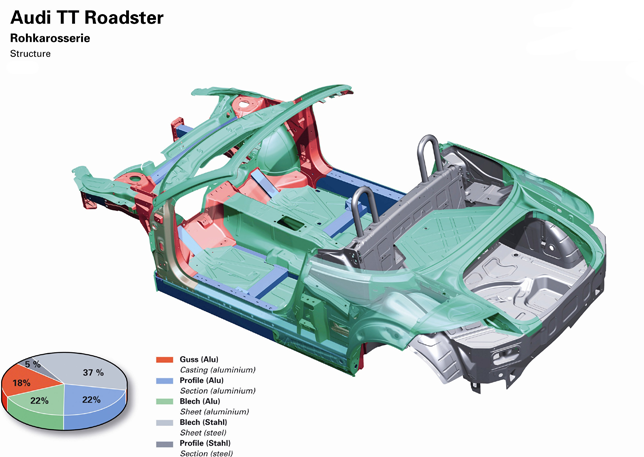

The TT Coupe and Roadster introduced a new variant of ASF technology, with steel used in addition to aluminum at certain points. This innovative hybrid construction principle cuts the car's total weight by as much as 100 kilograms compared with the previous models, which relied entirely on steel. At the rear of the floor pan in particular, for the doors and for the trunk lid, these compact Audi sports cars contain fully galvanized steel elements. Although these steel components weigh more than aluminum, they help to achieve well-balanced front and rear axle load distribution.

The TT 2.0 TFSI weighs only 1,260 kilograms unloaded – a splendid figure for a sports car. Its body weighs a mere 206 kg; this figure is made up of 140 kg of aluminum (68 percent) and 66 kg of steel. An equivalent body built in steel by conventional methods would be almost 100 kg heavier. The aluminum used in the body consists of 63 kg of sheet, 45 kg of castings and 32 kg of extruded sections. The Roadster tips the scales at 251 kilograms.

Audi's wealth of experience is invaluable when aluminum and steel components have to be joined. Various methods are employed: punch riveting, clinching and adhesive bonding. The problem of contact corrosion between these two metals has been solved by choosing adhesives that form an isolating layer. Camera systems monitor their correct application. A fourth joining technique is new: self-tapping screws inserted by robots generate friction that melts the surface of the component, so that they can penetrate completely into the material and form a rigid connection. Another innovative concept used on the TT is the aluminum zero-gap joint between the roof and the side section, which is produced by laser welding.

The Audi TT with its hybrid ASF, constructed in Ingolstadt, Germany, but shipped to Györ in Hungary for final assembly, has characteristics that suit a sports car outstandingly well. Compared with the previous model, the Coupe's static torsional rigidity is about 50 percent higher, while that of the Roadster in fact more than doubled. At the same time, however, there is a high level of freedom from bothering vibration and excellent crash impact absorption.

Low weight is one of the keys to captivating road dynamics and high efficiency. To reduce a car's weight by 100 kilograms is to improve its fuel consumption by about 0.3 l/100 km, and also to emit between 7.5 and 12.5 grams less of CO2 per kilometer. Customers and trade experts alike have praised this tendency: at the end of 2006, Audi's new hybrid body design principle received the Euro Car Body Award, the most important European trophy for innovation in body construction. Audi has already gained this award in 2003, for the ASF used for the Audi A8.